5 common failures of the pipeline centrifugal pump and its corresponding measures

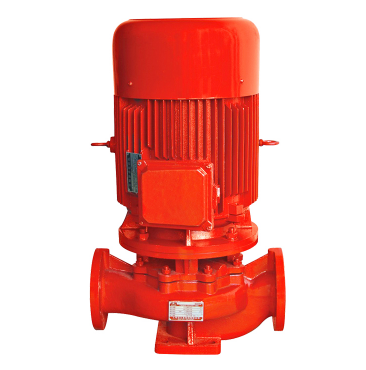

Pipeline centrifugal pump features:

1. The pump is compact in structure, small in size and beautiful in appearance. Its vertical structure determines that the installation area is small and its center of gravity is close to the center of the pump foot, thus enhancing the operation stability and service life of the pump.

2. The pump inlet and outlet are both horizontal, simplifying the pipeline connection.

3. The multi-stage type can be used as required, and the suction port and the discharge port can be installed in the same direction or several different directions of 90°, 180° and 270° to meet different connection occasions.

4. The pump pressure can be increased or decreased according to the need and the impeller outer diameter can be cut to meet it without changing the installation area, which is not available in other pumps.

5. The pump rotor has small winding, stable operation, small vibration, low noise, and long service life.

The solutions to the failure of the pipeline centrifugal pump

1. The pipeline centrifugal pump cannot be started or has a large starting load

The reasons and measures are as follows:

(1) The prime mover or power supply is not normal. The measure is to check the power supply and prime mover.

(2) The pump is stuck. The measure is to check with manual coupling and disassemble it if necessary to eliminate the static and dynamic faults.

(3) The packing is pressed too tightly. The measure is to loosen the filler.

(4) The discharge valve is not closed. The measure is to close the discharge valve and restart it.

(5) The balance pipe is not smooth. The measure is to dredge the balance pipe.

2. Pipeline centrifugal pump does not discharge liquid

The reasons and measures are as follows:

( 1 ) The filling pump is insufficient ( or the gas in the pump is not exhausted ). The treatment is to refill the pump.

( 2 ) The pump steering is not correct. The measure is to check the rotation direction.

( 3 ) The pump speed is too low. The processing method is to check the rotation speed and increase the rotation speed.

( 4 ) The filter screen is blocked and the bottom valve is ineffective. The treatment method is to check the filter screen and eliminate impurities.

( 5 ) The suction height is too high, or vacuum occurs in the liquid suction tank. The treatment method is to reduce the suction height; Check the suction tank pressure.

3. The pipeline centrifugal pump was interrupted after draining

The reasons and measures are as follows:

( 1 ) Air leakage in the suction line. The treatment method is to check the connection of the suction side pipeline and the sealing condition of the stuffing box.

( 2 ) When filling the pump, the gas on the suction side is not exhausted. The treatment is to require refilling the pump.

( 3 ) The suction side is suddenly blocked by foreign matter. The treatment method is to stop the pump to clear foreign matters

( 4 ) inhaling a large amount of gas. The treatment method is to check whether there is vortex at the suction port and whether the submerged depth is too shallow.

4. Insufficient flow

The reasons and measures are as follows:

(1) The system has a static head increase. The method of treatment is to check the liquid level and system pressure.

( 2 ) Increased resistance loss. The treatment method is to check the pipeline and check valve and other obstacles.

( 3 ) The abrasion of the shell and impeller wear ring is too large. The treatment is to replace or repair the wear ring and impeller.

( 4 ) Leakage from other parts. The treatment method is to check the shaft seal and other parts.

( 5 ) The pump impeller is blocked, worn and corroded. The treatment method is cleaning, checking and exchanging.

5. Pipeline centrifugal pump head is not enough

The reasons and measures are as follows:

( 1 ) The impeller is installed reversely ( double suction wheel ). The treatment is to check the impeller.

( 2 ) The density and viscosity of the liquid do not conform to the design conditions. The treatment method is to check the physical properties of the liquid.

( 3 ) Too much flow during operation. The solution is to reduce flow.