How to effectively extend the service cycle of the centrifugal pump to reduce the amount of maintenance? This has a great effect on improving the economic efficiency of the factory. Let's share the experience with the experts.

1. For the selection and installation of centrifugal pumps

Centrifugal pumps should be selected according to the liquid to be transported and checked for required performance, analysis of suction, discharge conditions, intermittent operation or continuous operation,...

More

Author: better fire pump

The self-checking methods of fire pumps

The self-checking method is a method for the daily inspection of the fire pump in the fire water supply system. In the self-checking of the fire pump, it can not only prevent the rust and jam of the fire pump, but also alarm when the motor overload, short circuit, overvoltage, phase loss, undervoltage, overheating, etc. The self-inspection of the fire pump is a kind of technological progress to improve the management level of the system.

In the two fire pump self-inspection methods, both can...

More

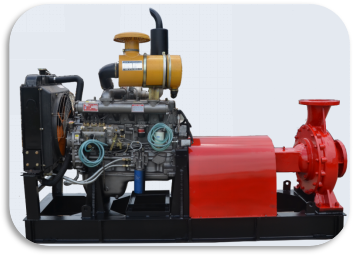

Customized ZJBetter fire pump set(25-10000gpm)

Better Technology Co, Ltd, focus on product fire pump set more than 17 years, our main product is fire pump and diesel fire pump set. The pump set range from 25-10000 gpm, pressure range 50-650 psi with different model type, like end suction pump, split case pump, vertical turbine pump.

https://youtu.be/FLcy73Qlzok

UL fire pump set

Flow: 200-500 GPM

Rated pressure: 103-224 PSI

NON-UL fire pump set

Flow: 120-3000 GPM

Rated Net pressure range: 50-180 m

Smal...

More

ZJBetter vertical turbine diesel fire pump & electric pump

ZJBetter vertical turbine pump are used for pumping normal temperature water and warm water under 100°C from wells, river, lake , sea. and used for city, factory dirty water and water containing great sand in river and sea, widely used in factories and mines, city and countries, petrolatum filed, plant and irrigation on farmland.

Flow: 25-5000GPM

Head: 50-300m

Impeller: alloy cast iron or silicon brass

Pump casing: alloy cast iron

Conical bush: stainless steel

Pump shaft:...

More

What causes the matching power motor of self-priming to overheat?

①The power supply.

The voltage is too high or low. Under a certain load, if the voltage fluctuation range is outside the rated value of +10% to -5%, the motor will overheat; the three-phase voltage of the power supply is asymmetrical, and the three-phase voltage imbalance exceeds 5%, which will cause the winding to overheat; Default phase will run, experience has shown that more than 85% of the agricultural motor burned is caused by the default phase operation, and the m...

More

Why does the self-priming pump cannot suction water?

The self-priming pump cannot suction water

Reason: there is air in the pump body or the gas in the water inlet pipe, or the bottom valve is not closed tightly and not filled with water, the vacuum pump packing is seriously leaking, and the gate valve or flap door is not closed tightly.

diesel self-priming fire pump

Measures: First press the water up, then fill the pump body with water, and then turn it on. At the same time, check whether the check valve is tight and whether there...

More

The self-priming pump common failures and solutions2 – Insufficient flow

3. Insufficient flow of self-priming pump

Reasons: the power speed is not matched or the belt slips, which makes the speed low; the blade installation angle of the axial flow pump is too small; the head is insufficient, the pipeline is too long or the pipeline has a right angle bend; the suction head is too high; the bottom valve, the pipeline and the impeller is partially blocked or impeller is defective; the water outlet pipe leaks seriously.

ZJBetter self-priming pump

Mearsures: re...

More

The self-priming pump common failures and solutions1

The self-priming pump cannot be started

First, check the power supply: whether the connector is firmly connected; whether the switch is in close contact; whether the fuse is blown; whether the three-phase power supply is equal. If there is an open circuit, poor contact, blown fuse, or missing phase, the cause should be found out and repaired in time.

Second, check whether it is a pump mechanical failure. Common reasons include: packing is too tight or the impeller and the pump body ...

More

How to deal with the failures of the diesel pump to start, heat, and insufficient flow?

Anyone who has used a diesel engine pump must have encountered some minor problems. If the pump is not used in accordance with its operation method during the use process, there may be a variety of fault problems. At this time, you must first check it clearly before you know what kind of problem, different problems also have different treatment methods.

1. The diesel pump set cannot be started

First, you should check the power supply: whether the connector is connected firmly; whether the...

More

Causes and treatment methods of low water output of submersible pumps

1. The filter of the submersible pump is blocked

Blockage of the submersible pump's filter screen will cause the water inlet of the pump to be unimpeded, and the water output of the submersible pump will be reduced. The treatment method is to remove the water plants and debris inside and outside the filter net and around the submersible pump. If necessary, use a bamboo basket or net basket to cover the submersible fire pump to prevent the entry of water and grass debris.

2. The rotation d...

More

The main points of fire pump selection

The fire pump has the advantages of full sealing, no leakage, and corrosion resistance. It is widely used in environmental protection, water treatment, fire protection and other departments to pump various types of liquids. It is an ideal pump for creating a leak-free, pollution-free civilized workshop and civilized factory. So how to buy a cost-effective fire pump?

The main points of fire pump selection

1. The flow and head of the fire pump should be calculated and determined according t...

More

How to select sewage pump,vertical and horizontal fire pump?

Key points in the selection of sewage pump:

Flow rate: The flow rate of the sewage pump should be selected according to the drainage second flow rate (measurement unit: L / s); when there is a displacement adjustment, the flow rate can be selected according to the discharge amount (measurement unit: m3 / h).

Electric fire pump

Head: The head of the sewage pump is determined after calculating the pipe loss according to the lifting height.

If the medium to be transported is a mixed li...

More

7 standards for fire pump selection

The selection of fire pumps is of great importance. Experts in the pump industry will explain the 7 major criteria for the selection of fire pumps for your reference.

Selection criteria for fire pump 1.

High efficiency, low noise, and energy-saving centrifugal pumps should be selected. It is strictly forbidden to select products for the obsolete products.

Selection standard of fire pump 2.

The voltage of the motor equipped with the centrifugal pump should be the same, and the powe...

More

What should I do if the impeller of the fire pump broke down and how to maintain it?

Fire pumps are now widely used in many fields. Although there are many applications, many people feel that the fire pump is broken when they have some failures, and they will be helpless. The following is a brief summary of some common fault inspections of fire pumps.

First, the fire pump is not provided with liquid or the liquid supply and pressure are insufficient. This situation may occur because of the following places:

1. Check whether the pump casing of the fire pump and inlet pip...

More

Why your fire pump cannot pump water? What is the fire controller inspection standard?

1. As the suction pipe of the self-priming fire pump is not tightly sealed, the self-priming fire pump is always in the state of pumping air.

The solution is to check the inlet pipe seal of the self-priming fire pump and repair the leak. For example, the welding place, pipe joint, etc. Try to run the fire pump about 5 minutes, then stop the machine, close to the pipe, and listen to the sound of air leakage.

2. Self-priming fire pump has been used for a period of time due to corrosion or a...

More

The difference between single stage pump and multistage pump.

With the development of science and technology, pumps at various levels have emerged endlessly and have been widely used. Some friends do not know about single stage pumps and vertical multistage pumps. Today the pump industry will introduce the difference between single stage pumps and multistage pumps.

Single stage pump refers to a pump with only one impeller, and the head is only 125 meters; multistage pump refers to a pump with two or more impellers, and the head can exceed 125...

More

Fire water supply is unstable. A water problem or a fire pump problem?

Stabilize fire water supply, make a proper fire pump selection and use

As we all know, the performance of the fire pump is an important factor affecting the system overpressure. For this reason, the correct selection and use of fire pumps can effectively avoid system overpressure. The specific measures are as follows:

First, you can choose a fire pump with a relatively smooth flow and head curve. Generally speaking, the pump's flow is negatively related to the head, that is, the...

More

The difference between fire pump and fire pump set

What are the differences between fire pumps and fire pump sets? To explain it simply, the fire pump set includes the fire pump, so let's see their differences in detail.

Fire pumps are used in a wide range of applications. In addition to supplying water for fire piping systems, they can also be used for industrial water supply. Fire pumps can also be used for water supply and drainage systems in cities. There are other relatively long-distance water delivery tasks, such as heating boilers, b...

More

Structure characteristics of vertical split case pump

At different stages of economic development, the corresponding product needs are also different. Recently, in the field of pumps, vertical split case pumps have become more and more popular.

The structure of the vertical split case pump is different from that of ordinary pumps. The suction port and the discharge port are horizontal. The separating surface of the pump body and the pump cover is vertically separated on the shaft centerline. This structure is particularly useful when the e...

More

what cause fire pump stuffing box overheating and its solutions

The fire pump is one of the mechanical products. Like other products, the fire pump may fail during use. Among them, stuffing box overheating is a more common failure in fire pump failures.

the stuffing box is not properly packed. Insufficient packing, or improper plugging or running-in, and too tight packing may cause the stuffing box to overheat. To solve this problem, it is necessary to check the condition of the packing and readjust or refill the packing.

The filling or sealing of th...

More

What factors determine the fire pumps efficiency?

What factors determine the fire pumps efficiency?

The fire pump itself

The fire pump efficiency is one of the main factors. Different fire pumps often have different efficiency, but the same fire pump type under the same working conditions, there is also a deviation in efficiency, the gap is often around 15%.

Whether the operating conditions are consistent with the rated conditions

Generally speaking, the operating conditions of fire pumps are lower than the rated operating conditions of...

More

How to stop the diesel engine fire pump correctly

How to stop the diesel engine fire pump correctly

After the diesel water pump outputs the foam mixture, it should be immersed in clean water for 2 minutes to clean the pump body parts and avoid the residual foam liquid corrosion.

When stopping, close the small throttle, let the engine idling for 2 minutes to make the cooling uniform, and then accelerate the idling for 2-3 seconds to make all components fully lubricated and then stop.

After stopping, disconnect the circuit and remove t...

More

How to install the fire pump? How many installation ways?

How to install the fire pump? How many ways can I install a fire pump?

The installation of fire pumps needs to pay attention to many aspects. Different fire pumps have different types of installation requirements. Generally speaking, there are the following types:

Hard connection installation

Because the vibration of the fire pump is very small, the fire pump bottom plate can be directly installed on the pre-cast cement foundation, which can meet the use requirements and is suitable f...

More

6 major faults and troubleshooting of the sludge pump

Sludge pump is a kind of pump that is commonly used in sewage treatment and construction projects. Users can understand and learn the application knowledge of the sludge pump, which can greatly improve the service life and maintenance cost of the mud pump.

1. The sludge pump is slow to pump water.

Reason: The gap between the front lining plate and the impeller is large, the water outlet pipe can not seal the air;

The elimination method: adjusting the gap, adjusting the water outlet pipe, and ins...

More

The application conditions of vertical turbine fire pump

The vertical turbine fire pump is the professional name of the dry motor fire pump. The motor is a dry motor and is not immersed in water. There is an "axis" inside the water pipe. It is suitable for extracting groundwater from deep wells or pools. It is also suitable for water extraction projects such as rivers, reservoirs, and canals. It is mainly used for farmland irrigation and water for humans and animals in plateau mountainous areas. It can also be used for city, factory, railway, mine, co...

More

The common materials for fire water pumps – ZJBetter

First, cast iron

Gray cast iron is the most commonly used type of cast iron, the national standard code is ht. Generally, the pump body, impeller, pump cover, suspension, etc. of the clean water pump (diesel water pump) use this material, three popular brands: ht150, ht200, ht250. Ht150 is used for non-main components such as base and gasket, ht200 is used for pump body, pump cover, suspension, etc. ht250 is used for impeller, ring, bushing, etc. The expression patterns of gray iron in differen...

More

Mobile Trailer Mounted Pump Maintenance

As a city construction and fire standby equipment, mobile pump trailers are innovative technology products that we often use and see. We will tell you the operation process when pumps were delivered from the factory and received by customers. However, how many do you know about the maintenance of mobile pump trailers? Let's learn about the maintenance of the mobile pump trailer.

1. Pumping mechanism part

Before using the car, fill the washing room with clean tap water. When the outside tem...

More

The reason of fracture of pump shaft of diesel engine fire pump

In the process of using the diesel engine fire pump, if the pump shaft breaks, many people will blame the product quality problem. In fact, this is not correct. The cause of the diesel engine fire pump shaft break is not only caused by product quality. The irregularity of the operation is the main problem.

The precision of the pump shaft casting is not enough, which leads to the fracture of the pump shaft of the fire pump;

The heat treatment of the diesel engine fire pump shaft is no...

More

Centrifugal pump structure in fire fighting pump – ZJBetter

The centrifugal pump in the fire pump, we simply talk about its structure, the basic structure of the centrifugal pump is composed of eight parts: impeller, pump body, pump cover, water retaining ring, pump shaft, bearing, seal ring, stuffing box, axial force balancing device.

The impeller is the core part of the centrifugal pump, and its output speed is high.

The pump body is also called the pump casing, which is the main body of the pump. It acts as a support and is attached to the bra...

More

Self-priming pump installation precautions – ZJBetter

The self-priming pump has the advantages of compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long service life, and strong self-priming capability. The pipeline does not need to be installed with a bottom valve. It is only necessary to ensure that the pump body has a quantitative liquid before storage. After buying a self-priming pump, how to install, and what should you pay attention to?

Self-priming pump installation precautions

Before insta...

More

The key factors of sewage water pump prices

What kind of sewage pump is good? How to buy a sewage pump correctly? The reason why sewage pump prices are high or low, the common reason is that the technical advantages of sewage pumps. Different production companies, technologies, performance advantages, must have different prices. Then, behind the sewage pump price, what scientific and technological strengths need to be considered?

The key factor one: the level of sewage discharge capacity

In general, the sewage pump first depends on its ...

More

How to select a water pump? — ZJBetter

A water pump is a machine that delivers or pressurizes a liquid. It is mainly used to transport liquids including water, oil, acid and alkali, emulsions, Intralipids, and liquid metals. It can also transport liquids, gas mixtures and liquids containing suspended solids. In this era of rapid industrialization, the important line of pumps has gradually expanded.

How to select a water pump?

Performance is the key one

In general, pumps can be classified by industry, principle, use, performa...

More

5 Tips to Select a Right Sewage Pump? – ZJBetter

Better Technology Co., Ltd. has been engaged in the pump industry for more than 16 years and has developed and produced numerous types of sewage pumps. Have to say the variety of products will let customers confused about the choice of sewage pumps. How to select a sewage pump?

Today, the company's engineering designers have made a summary of this for the customers.

5 Tips to Select a Right Sewage Pump Model:

Customers before the selection, first consider the practical use. Generally speaking...

More

What decreases the efficiency of the fire pump during operation?

What decreases the efficiency of the fire pump during operation?

The fire pump is an important part of the fire protection system and has a great responsibility for safety. The operating efficiency of the fire pump directly determines the working efficiency of the fire protection system. Sometimes, we may find that the operating efficiency of the fire pump has dropped. What is the reason? We will analyze several possible reasons for the decline in the efficiency of the fire pump.

The volume ...

More

KDZY diesel engine mobile pump application

KDZY diesel engine mobile pump is a flood-preventing and drought-resisting savior. It has a large-volume, fully intelligent control, free-maintenance, and universal function mobile pump. The air-cooled engine is activated by artificial energy storage, which not only eliminates the maintenance of battery and fan water tank cooling system, and it can work in harsh environments such as extremely high temperatures, low temperatures, and dust. In the case of long-term storage, the equipment can go to...

More

How to better use a fire pump?

The inside of the fire pump pressure tank is divided into two parts by a diaphragm made of rubber, and one side is connected to the pipe, which is called a water storage chamber. There is air on the other side, called the gas storage room.

The air stored in the air storage chamber is responsible for adjusting the internal air pressure. By utilizing the characteristic that the air can be compressed, the air pressure is compressed by pressing the intermediate diaphragm, so that the diaphragm is...

More

How to use the fire pump safely?

How to use the fire pump safely?

Because the fire pump plays a great role in fire safety, a slight error will bring unpredictable consequences. More leather is the time when our situation is fast and fire.

Therefore, the fire pump needs to do the following during the operation:

In the case of driving, it is necessary to do a close inspection.

In the process of management. Fire pump, diesel fire pump, vertical fire pump, fire pump manufacturer, electric fire pump, fire pump manufactur...

More

Electric vertical fire pump features and working conditions

The Electric vertical fire pump meets the requirements of fire pumps in terms of performance, structure, materials, and accessories. Due to the hydraulic model, this series of pumps meet the requirements: it adopts vertical pump structure, which has the characteristics of high efficiency and wide performance range, which can better save the advantages of floor space. It adopts bearing and electrolysis to make the pump run. It is safer and more reliable, has low noise and low vibration. It adopts...

More

How to select a vertical turbine pump? – Better Technology Co., Ltd.

(1) Select a submersible multiple stage pump based on the maximum allowable production of the source well. The pump volume of the pump must be consistent with the actual water inflow in the well. The pump volume must be equal to or slightly less than the real production of the water source well. Otherwise, strong pumping will be produced, which will not only shorten the service life of the vertical turbine submersible pump, but also filter it in severe cases. The net is damaged, causing the sand...

More

How to improve the operation stability and prolong the service life of single stage fire pump?

How to improve the operation stability and prolong single stage fire pump life expectancy?

Single stage fire pump product features:

The pump is compact in structure, small size and fine appearance. The vertical structure has a low center of gravity and the center of gravity coincides with the center of the pump foot, which enhances the running stability and pump service life.

Easy to install. The inlet and outlet diameters are the same and on the same centerline, and can be directly i...

More

What are the advantages of vertical multistage fire pumps?

What are the advantages of vertical multistage fire pumps?

The new vertical multistage fire pump does not have a final guide vane in the water outlet section. After the final impeller is released, the water directly enters the volute-shaped flow passage of the outlet section and then is discharged from the outlet. The new vertical multistage fire pump comprises a water inlet section, a middle section, a water outlet section, an impeller, the main shaft, and a guide vane, wherein the impeller ...

More

Why is the fire pump pressure low and low pressure troubleshooting?

When many people use the fire pump, fire pump can’t reach the pressure the fire pump required. The user will directly contact the fire pump manufacturer to solve it. However, the reason why water pump pressure is not enough is the water supply, and the outlet end is over-treated, a large amount of air in the pump chamber that is not discharged, or even error wiring methods.

For the lack of pressure on the fire pump, there are several possibilities and solutions for the pressure:

9 test met...

More

How to install the fire pump correctly?

How to install the fire pump correctly

Do you know the requirements for installation of fire pumps? How much do you know about the fire pump, How to install the fire pump correctly, in order to make better use of its advantages. Let's take a look.

1. The installation location of the fire pump should be as close as possible to the water source of the fire water and choose the appropriate distance.

2. Check the condition of the fire pump before installation. Generally, when the fire pump is...

More

Why does the pipeline sewage pump not pump water?

1. There is a crack at the elbow of the sewage pump inlet pipe, and a slight gap occurs at the connection between the inlet pipe and the water pump, which may cause air to enter the inlet pipe.

2. The sewage pump is not filled with enough water before starting. Sometimes it seems that the water has overflowed from the venting hole, but the air is not completely discharged from the pump shaft so that a little air remains in the inlet pipe or the pump body. The pump speed is too low.

3. The pack...

More

How to test the fire pump seal? – Better Technology Co., Ltd.

Fire pump seal, is one of the key factors to measure the quality of the fire pump, so how to detect fire pump sealing? What are the requirements of seal ring inspection?

1. The surface of the auxiliary sealing ring is smooth, and shall not have defects such as bubble crack notch; End size should be uniform; Rough edges of O ring seal keeps at a 45-degree angle to working face. Once the sealing ring appears bubbles and crack, it suggests that the sealing ring is leaky. Therefore, fire pump in...

More

7 Common vertical turbine pump failures and troubleshooting

The vertical turbine pump is circulating water pump, located in the circulating water system, and the over-flow medium is sea water. The function is to provide flushing water for the drum-type rotating filter to ensure that impurities and sea creatures are washed away in time, thus bringing clean seawater downstream. The vertical turbine deep well pump is installed in the seawater water intake platform outside the circulating water pump room, and the seawater is sucked from the drum filter pool....

More

2 factors to determine the number of fire pumps for the plant

With the development of the economy and the progress of society, the enterprise factory building is now growing. The fire rescue of the plant is obviously related to the area of the plant and the combustibles it contains. Of course, there are also key factors that firefighting self-service equipments are incomplete.

Then, the manufacturing enterprise has a large factory area, and how should the fire safety equipment be equipped? Perfect fire safety equipment, how many fire pumps are needed? H...

More

Preparations must be made before the diesel engine fire pump starts

Preparations must be made before the diesel engine fire pump starts

Because the diesel engine fire pump set is not limited by the power supply, it can be better to provide safety for fire emergency. At the same time, the speed control function of the diesel engine makes the use and performance of the equipment more extensive, and the pressure and flow adjustable performance are further improved. With the continuous development of industrial automation, the pump is also equipped with a fully a...

More

The Secret of Extending the Service Life of Vertical Turbine Fire Pumps

Vertical turbine fire pumps, in the field of fire pumps, are small in demand, but they are also indispensable in some areas of daily life. Vertical turbine fire pumps are widely used in industrial and mining enterprises, engineering construction, and high-rise buildings. Today's environment is still the same, but product performance has been improved.

With the advancement of technology, the development technology of vertical turbine fire pumps are better than ever before, scientific, effectiv...

More

What causes the fire pump overheating?

Different types of fire pumps may have different faults and different frequencies. Today, let's explore the reason what causes the fire pump overheating?. how to deal with it?

First, The motor

The fire pump motor overheat. First of all, it is necessary to consider whether the motor has broken down. For example, the connection of the relevant line is wrong, resulting in a rapid increase in the temperature of the motor. Or, the stator winding of the motor has a phase-to-phase short circuit, a ...

More

The Secret of Multistage Fire Pump Selection

Multistage fire pumps are widely used in environmental protection, water treatment, fire protection, and other industries. Choosing a cost-effective multistage fire pump product can not only improve product efficiency, but also reduce costs. Therefore, the selection of multistage fire pumps is particularly important. Today we will discuss how to choose a multistage fire pump?

1. Use the pump performance comprehensive spectrum to select the pump type.

The working areas of the centrifugal pump...

More

Booster pump is indispensable for high-rise building firefighting

As the buildings get higher and higher, when they occur fires in high-rise buildings, the escape problem becomes more and more serious. Correspondingly, fire fighting in high-rise buildings is becoming more and more critical. So, what factors affect the efficiency of fire suppression in high-rise buildings? On this issue, I will discuss it with you today.

Two factors are indispensable for High-rise building fire fighting

Firefighter physical fitness

Firefighters will have sufficient firefig...

More

Why does the fire pump rust? – Better Technology Co., Ltd.

Why does the fire pump rust? What are the causes of the fire pump corrosion? Better Technology Co., Ltd. focuses on the development and production of fire pumps, and always solves equipment failures for fire pump users. Recently, many new and old customers said that in order to effectively extend the life of the fire pump, it is necessary to control the rust of the fire pump from the source. To this end, I am here to briefly explain the fundamental factors of the fire pump rust.

Material factor...

More

The water pressure test is the fire fighting pump final test

The water pressure test is the fire pump final test

The fire pump is one of the engineering equipment for fire safety protection and one of the more important ones. The performance index and reliability of the fire pump determine the quality and performance of the entire fire protection system.

For this reason, when a fire pump is produced, it needs to pass through layers of tests and tests before entering the user's hands. Among them, fire pumps often do a lot of tests before leaving the facto...

More

Integrated prefabricated pump station installation instructions

The integrated prefabricated pumping station is from the planned single row of d2000mm rainwater pipelines. The influent water is connected to the grille to crush the dirt, and then the water is evenly distributed to the three prefabricated pump wells through the water distribution tank. After the submersible sewage pump is lifted, it passes through 3 DN1200mm pipelines. The collection is a DN1800mm pipeline, and a butterfly valve is arranged on the DN1800mm pipeline for maintenance. A moisture-...

More

What are the reasons that affect the performance of self priming pumps?

What are the reasons that affect the performance of self priming pumps?

The self priming of the self priming pump means that the suction pipe does not need to be filled with water (but there must be enough water in the pump body) to start, and the function of automatically removing the gas in the suction pipe is performed, and the normal operation is performed after a short time operation.

Determination of the storage volume and liquid storage height of the self priming pump:

The liquid stor...

More

Sewage lift pump station failure causes and troubleshooting methods

The sewage lift pump station is a key process of the urban sewage treatment plant and plays an important role in the normal operation and operating costs of the entire sewage treatment plant. In daily operations, it is difficult to avoid unnecessary failures. To master the troubleshooting method of the sewage pump lift pump, you must know its working principle, structural structure, and necessary operational skills and mechanical maintenance knowledge. With this knowledge, you can find unusual c...

More

Submersible sewage pump maintenance tips

The submersible sewage pump is a kind of pump type which is connected with the pump and the motor and is submerged under the liquid. It is suitable for various occasions. In order to make the equipment last longer, you need to know about the submersible sewage pump maintenance techniques.

Determine the correct direction of rotation of the motor

The direction of rotation of the motor should be clarified. Nowadays, there are many types of submersible sewage pumps that can discharge water during ...

More

What are the advantages of an integrated pumping station?

High integration

The integrated lift pumping station is an integrated unit, and its complete set provides prefabricated cylinder, submersible sewage pump, piping system, pulverizing grid, intelligent control system, lifting device, an exhaust device, etc., which can fully satisfy different types requirements of users.

Strong, Fine

The main body of the integrated pumping station is made of fiber-wound FRP, It is completely resistant to tearing, corrosion and other destructive force...

More

Integrated prefabricated pumping station

In contemporary society, people's awareness of environmental protection is weak, and many sewage is directly discharged into rivers, resulting in water pollution. At present, sewage treatment methods are single and require manual transportation, and the efficiency of treatment is low. In order to change this situation, Better Technology Co., Ltd. has developed and produced an integrated prefabricated pumping station, which has become a "tool" for handling these fields.

Basic overview:

The ...

More

WQ submersible sewage pump performance characteristics and precautions

The WQ submersible sewage pump uses a unique structure and a new mechanical seal to efficiently transport solids and long fibers. Compared with the conventional impeller, the impeller is in the form of a single flow channel or a double flow channel. It is similar to a curved pipe of the same cross-section. It has very good over-flow and is equipped with a reasonable volume to make the pump efficiency, and impeller dynamic and static balance test, so that the pump has no vibration during operatio...

More

Five differences between the IS horizontal centrifugal pump and the vertical centrifugal pump

The IS horizontal centrifugal pump is the multistage segmented type, the suction port is located on the water inlet section and is horizontally oriented. The discharge port is vertically upward on the water section, and the head can increase or decrease the number of pump stages according to the needs of use. Whether the horizontal centrifugal pump is well assembled or not has a great influence on the performance, especially the inlet and outlet of each impeller and the guide vane. The slight de...

More

Centrifugal pump won’t start and low discharge pressure problem?

Centrifugal pump won't start and low discharge pressure problem?

During the operation of the centrifugal pump, various centrifugal pump failures will inevitably occur. Therefore, how to improve the reliability, life, and efficiency of pump operation, and timely and accurate judgment of the occurrence of faults is an important means to ensure the smooth operation of production. Here are two centrifugal pump problems and solutions.

The most common fault diagnosis and treatment methods for cent...

More

Integrated Prefabricated Pumping Station – Better Technology CO., LTD.

Integrated prefabricated pumping station (hereinafter referred to as pumping station) is a new type of environmental protection next-generation pumping station that lifts sewage, rainwater, drinking water, wastewater, etc., and is designed, manufactured, assembled and transported to the site for installation.

Pumping station series products have the characteristics of short construction period, convenient installation, small size, high efficiency, intelligent network, and other modern pro...

More

how does a centrifugal pump work?

How does a centrifugal pump work?

When the centrifugal pump is working, it relies on the impeller that rotates at a high speed, and the liquid obtains energy under the action of inertial centrifugal force to increase the pressure. Before the centrifugal pump is working, the pump body and the inlet pipeline must be filled with a liquid medium to prevent cavitation.

When the impeller rotates rapidly, the blade causes the medium to rotate rapidly, and the rotating medium flies out of the impell...

More

How to choose diesel engine water pump?

How to choose diesel engine water pump?

When the user chooses the diesel water pump, it is best to go to the sales point approved by the agricultural machinery department and be sure to recognize the manufacturer. It is recommended to give priority to the purchase of water-filled submersible pumps and to see the brand and product quality certificate. Never buy a "three no" (ie no manufacturer, no production date, no production license) products, otherwise, there will be problems, users will be ...

More

Installation of Diesel Self Priming Pump

Installation of Diesel Self Priming Pump

1. When the pump and the motor are directly connected, the coaxiality of the pump shaft and the motor output should be paid attention to; the accuracy of the pump installation has a great influence on the smooth running and service life of the pump, so it must be carefully and carefully installed, and correction.

2. the pump coupling must be fastened with the female mother, and lock the nut, beware of loosening the mother, otherwise, it will cause the...

More

The Selection of Deep Well Pump – Better Technology CO., LTD.

(1) Select a submersible multistage pump based on the maximum allowable production of the source well. The pump volume of the pump must be consistent with the actual water inflow in the well. The pump volume must be equal to or slightly less than the actual production of the water source well. Otherwise, strong pumping will be generated, which will not only shorten the service life of the deep well submersible pump, but also filter it in severe cases. The net is destroyed, causing the sand to st...

More

Reasons for the oil pressure drop of the diesel engine pump set

The normal oil working pressure of the diesel engine pump set should be between 0.25-0.35 MPa, which can be higher when the new machine or machine temperature is low, and lower when the old machine or machine temperature is high. When the machine is working, if the oil pressure is lower than 0.2MPa or it changes with the speed, it will suddenly drop to zero, indicating that there is a problem in the machine. It should be turned off immediately to find the cause, and the fault can be restarted. O...

More

Diesel Engine Fire Pump Precautions in Use

Diesel engine fire pumps are usually used in fire-fighting facilities and play a very important role. How can diesel fire pumps fully play their role? First, we should maintain good usage habits in use. Problems that should be noted during use.

First, the inspection before use is very important. Before turning on the diesel fire fighting pump, the pump body and other facilities should be inspected in detail. If there is excessive wear or rupture of the parts, it must be replaced in time. Smal...

More

How to correctly set up the fire pump? – Better Technology CO., LTD.

1. In general, fire pumps should adopt self-priming water absorption.

2. When the fire pump is directly pumped from the municipal pipe network, a backflow preventer with air partition shall be provided on the outlet pipe of the fire pump.

3. When there is no water absorption well at the water suction port, a swirl preventer should be installed at the water suction port.

4. A group of fire pumps should have no less than two suction pipes. When one of them is damaged or repaired, the other suct...

More

How Does a Diesel Engine Work?| Diesel Engine Working Principle

Like a gasoline engine, a diesel engine undergoes four processes of intake, compression, work, and exhaust per work cycle. However, since the viscosity of diesel is larger than that of gasoline, it is not easy to evaporate, but the self-ignition temperature is lower than that of gasoline. Therefore, the formation and combustion of the combustible mixture of the diesel engine are different from that of the gasoline engine. The diesel engine sucks in the intake stroke pure air. When the compressio...

More

How to choose a pump model and specifications correctly?

Pumps are an essential life tool for every family, and while most people don't realize it, it's true. Many people know nothing about pumps. Below we will give a brief introduction to the classification and model specifications of the pump.

Classification of pump selection:

1. According to the working principle and structure of the pump:

Vane pumps, positive displacement pumps (and other types of pumps) such as: jet pumps, air lift pumps, electromagnetic pumps, vacuum pumps, etc.

Vane pumps such...

More

Pneumatic Diaphragm Pump Application Notice

Pneumatic Diaphragm Pump Application Notice

The pneumatic diaphragm pump is a volumetric pump that uses compressed air as the power to change the volume through the reciprocating deformation of the diaphragm. Its working principle is similar to that of the plunger pump. The pneumatic diaphragm pump is used according to certain principles and methods. It can be used according to certain instructions and precautions in the specific operating procedures, which can produce important use effects and ...

More

The diaphragm pump selection – Better Technology CO., LTD.

The diaphragm pump consists of an actuator and a valve. The diaphragm pump actuators are pneumatic actuators and electric actuators, models are QBY pneumatic diaphragm pumps, QBK pneumatic diaphragm pumps, and DBY electric diaphragm pumps. The main body (valve body) of the diaphragm pump is made of four kinds of materials: plastic, aluminum alloy, cast iron, and stainless steel, which are selected according to the requirements of the liquid or gaseous medium. The diaphragm inside the diaphragm p...

More

Five characteristics of water pump selection – Better Technology CO., LTD.

A water pump is a machine that delivers or pressurizes a liquid. It transfers the mechanical energy of the prime mover or other external energy to the liquid and increases the energy of the liquid. It is mainly used to transport liquids including water, oil, acid and alkali, emulsion, suspoemulsion, and liquid metal, and also to transport liquids and gas mixtures. And a liquid containing suspended solids. The water pump selection should be based on the process flow, water supply, and drainage re...

More

4 Irrational applications of horizontal multistage centrifugal pump

When using a multistage centrifugal pump, it is inevitable that there will be some mistakes in use, but I can't find it in time, sometimes even because of this mistake, the pump is damaged, then what are the misusages of the general horizontal multistage centrifugal pump? What?

1. Large diameter pump with small water pumping

Many operators think that this can improve the actual lift, in fact, the actual lift of the pump = total lift - loss head. When the pump model is determined, the total lif...

More

Two Types of Fire Pumps Self-checking Methods

Two types of fire pumps self-checking methods, the self-checking effect on the fire pump can be reflected. However, the low-speed self-test mode only runs a preliminary stage in the start of the fire pump, which cannot fully reflect the actual operation of the fire pump in the future. Working conditions. In addition, after the results of the self-inspection of the fire pump are fed back to the fire control center, further judgments need to be made manually. Therefore, the fire pump self-test met...

More

The Analysis of The Fire Pump Selection

The Analysis of The Fire Pump Selection

The fire pump selection needs to take into account the influence of various factors. In general, the priority of these influencing factors in the fire pump selection is as follows.

(1) Impact analysis of fire pump selection operation reliability

As a fire rescue equipment for offshore oil and gas fields, the operational reliability of fire pump selection is the most critical design control factor for fire pump selection. Designers need to fully consider ...

More

Plastic pump in the future engineering applications will have great prospects

Plastic pump is an important branch of the pump family. The main reason is that the plastic pump is made of engineering plastics, so it has certain advantages in performance and operability. At present, the utilization rate of plastic pumps is increasing year by year. Enterprises have begun to start plastic pumps, and plastic pumps are invading the wider market, showing a trend of blooming everywhere in the country.

Plastic pumps are very important in engineering. Because the performance of pla...

More

What are the precautions for using the submersible sewage pump?

What are the precautions for using the submersible sewage pump?

Before the pump is started, the system should be inspected by a qualified electrician to ensure the following electrical protection measures required for each of the followings:

Before the pump is running, use the 0~500 megohmmeter to check the phase and relative insulation resistance of the motor. The minimum value should be greater than 2MΩ;

The power supply unit should be safe, reliable and normal. The power supply voltage ...

More

Pneumatic diaphragm pump can also be used effectively in harsh environments

The role of the pneumatic diaphragm pump in the industrial field is very important. It can be used in harsh environments such as flammable and explosive, and it can do a lot of work that is difficult for the human to do, ensuring the safety of workers and reducing economic losses.

The pneumatic diaphragm pumps are reliable and low cost in pneumatic and flammable environments, and the fluid does not overheat because the diaphragm pump minimizes fluid agitation. In places with poor construction s...

More

How to select sewage pump – peerlesspumpparts

How to select the sewage pump

The sewage pump currently visible on the market is often referred to as a non-blocking sewage pump. Is it true that there is no blockage? Not necessarily! Often the user's sewage pump is blocked by debris in the sewage pool for a long time. The motor burned down, how to choose the sewage pump, which made many users nervous...

The selection of the sewage pump

The most critical problem for the sewage pump is the reliability problem, because the medium to be transporte...

More

Repair method after the wear of constant pressure fire pump

As we all know, in the event of a fire in a high-rise building, it is often necessary to build a self-rescue for each high-rise building based on a bolting system or a sprinkler system. In other words, it is vital that high-rise buildings rely mainly on their own facilities. Here, the fire-fighting facilities of the constant-pressure fire-fighting water supply equipment can be used to complete the fire rescue. To this end, let's talk about a little fire pump startup advice.

First of all, we s...

More

The diaphragm pump maintenance can extend its service life

The diaphragm pump is one of the most common pumps on the market. With its superior performance, it has won the hearts of a large number of users and is fortunate to be the leader in the market. The market share is far superior to other products on the same scale. However, products with better quality and superior performance need to be overhauled, which is an important way to guarantee the life of the products. Experiments have shown that the failure rate of products without maintenance is much...

More

Three Faults of the Submersible Pump – Better Technology CO., LTD.

Due to the working environment and time factors of the submersible pump, some troubles will occur. In order to improve its working efficiency, let us analyze the faults of the submersible pump.

One. The submersible pump has abnormal vibration and instability.

Main reasons:

The pump base anchor bolts are not tightened or loose.

The outlet pipe is not supported independently, and the pipe vibration affects the pump.

Impeller mass is unbalanced or even damaged or loosely installed.

The u...

More

The portable fire pump maintenance – Better Technology CO., LTD.

The portable fire pump maintenance

1. Maintenance

The portable fire pump maintenance should be carried out in a ventilated and dry place. External dust and oil stains should be removed and the amount of lubricating oil should be checked on schedule.

after use, lubrication in various motion states should be protected. The spark plug should be removed for inspection when the pump rotates for a cumulative 50 hours. The pump should operate for a cumulative 100 hours to remove the carburetor and rem...

More

Composition, Classification and Application Scope of the Portable Fire Pump

The portable fire pump is a kind of fire pump which is directly connected with the light engine and water pump and can be carried away by manpower to save common material fire and small oil fire. Due to the advantages of portable and flexible portable fire pump, it is not restricted by traffic, power and regional obstacles, and has been widely used to fight the initial fire in places where roads such as industrial and mining enterprises, warehouses, ports, docks, and rural areas have poor traffi...

More

How to select the sewage lift pump? 9 parameters should be considered

How to select the sewage lift pump? What parameters should be considered?

We often wonder how are the rain on rainy days, the sewage from construction sites, the sewage from bathing, and the dirty water disposed of and discharged into the city's pipelines. I will tell you that sewage treatment and discharge requires our professional sewage treatment equipment – sewage lift pump. And what kind of sewage pump is good, how should we choose the brand of sewage pump? Then I will explain to everyone t...

More

Submersible Well Pump Maintenance – Better Technology CO., LTD.

Submersible Well Pump Maintenance

Before using the submersible pump for wells, the insulation resistance of the motor must be checked with a megohmmeter, and its value must not be less than 50mΩ.

The water immersion motor should open the irrigation plug and tighten the plug after filling it with clean water. Do not screw off the irrigation plug and run it directly into the well.

Check whether the cable is cracked or broken before use. If there is any damage, it should be replaced in time ...

More

Common Trouble Causes and Solutions of Submersible Well Pump

Common Trouble Causes and Solutions of Submersible Well Pump

Failure 1

No water out, waterless or intermittently water out.

Causes: ① Motor reversal; ② The motor did not start; ③ The dynamic water level is lower than the suction port; ④ Serious leakage of pipelines or connecting parts; ⑤ The pump seal ring or impeller serious grinding damage; ⑥ The motor and pump shaft sleeve are moving.

Solutions: ① Change the contact position; ②Eliminate the line trouble, check the voltage; ③ Increase the ris...

More

Inspection and Installation of Submersible Well Pump

Inspection and preparation before installation

(1) Check whether the well meets the use conditions of the pump, i.e. the well diameter, vertical and borehole wall quality, as well as the static water level, dynamic water level, water inflow and water quality conditions, etc. If it does not meet the use conditions, corresponding measures must be taken, otherwise the pump cannot be lowered into the well.

(2) Check whether the power supply equipment and power supply lines can guarantee the normal...

More

Submersible Pump Structure and Working Principle for Well

Submersible pump structure for well

Submersible pump for well is composed of the pump body, lifting pipe, pump seat, submersible motor ( including cable ) and starting protection device. The pump body is the working part of the submersible pump and consists of parts such as water inlet section, guide shell, check valve, pump shaft and impeller. The impellers are fixed on the shaft in two ways: 150QJ30, 200QJ80, 250QJ80 and QJC impellers are fastened to the pump shaft with conical sleeves. Oth...

More

Pipeline centrifugal pump maintenance – Better Technology CO., LTD.

Pipeline centrifugal pump maintenance - Better Technology CO., LTD.

Maintenance in operation

1. The water inlet pipe must be highly sealed and cannot leak water or air.

2. It is forbidden for the pump to run under cavitation;

3, try to avoid the pump running under the condition of large flow;

4, regularly check the motor current value; Shall not exceed the rated current of the motor;

5, the pump should be in charge during the operation to avoid accidents;

6. The pump refuels the bearings...

More

5 misunderstandings of water pumps in mechanical seal inspection

5 misunderstandings of water pumps in mechanical seal inspection

1) The larger the amount of spring compression, the better the sealing effect. In fact, if the spring compression amount is too large, the friction pair may be sharply worn and burned instantaneously; excessive compression causes the spring to lose the ability to adjust the end face of the moving ring, resulting in seal failure.

2) The tighter the moving ring seal is, the better the sealing effect. In fact, the dynamic ring sea...

More

The screw pump applications in sewage treatment

The screw pump applications in sewage treatment

The screw pump is widely used in sewage treatment plant to transport water, wet sludge and flocculant liquid medicine because it has the characteristics of variable transportation, strong self-priming ability, reversibility and the ability to transport liquid containing solid particles. The selection of screw pump should follow the principles of economy, rationality, and reliability. If the screw pump design and selection of screw pump are not cons...

More

5 common failures of the pipeline centrifugal pump and its corresponding measures

5 common failures of the pipeline centrifugal pump and its corresponding measures

Pipeline centrifugal pump features:

1. The pump is compact in structure, small in size and beautiful in appearance. Its vertical structure determines that the installation area is small and its center of gravity is close to the center of the pump foot, thus enhancing the operation stability and service life of the pump.

2. The pump inlet and outlet are both horizontal, simplifying the pipeline connection.

3. The ...

More

What causes the diesel fire pumps to enter the air?

In the use of the diesel fire pump, if the diesel fire pump enters the air, the user should do a good job to prevent it from affecting the normal use of the later period. The following is an analysis for everyone.

1) The diesel engine fire pump is not filled with enough oil before starting; it seems that the oil has overflowed from the venting hole, but the air is not completely discharged from the pump shaft so that a little air remains in the oil pipe or pump body.

2 ) The oil level ...

More

How to stop the diesel engine fire pump rightly?

How to stop the diesel engine fire pump rightly?

The diesel engine fire pump can be installed together with the fire control cabinet. It has complete functions, high-degree automation, compact structure, automatic fault alarm and receiving the start signal. It can complete the starting procedure by itself and can quickly put into full-load operation. The unit can be equipped with the damper, rubber flexible joint and exhaust port with bellows silencer as required. Insufficient fuel, low battery...

More

These fire pump installation details you need to know – Better Technology CO., LTD.

It is well known that the use of fire pumps is affected by the installation. Whether the installation is correct or not, the details are in place, which seriously affects the use effect and lifespan of the fire pump.

These fire pump installation details you need to know

First of all, with the development of science and technology, the technology of the current fire pump is more and more advanced, and the vibration is not as large as before. Therefore, it is recommended to install the fire pump...

More

Centrifugal Pump Flow Control Method – Better Technology CO., LTD.

Centrifugal Pump Flow Control Method

Method 1: The Export valve opening adjustment

In this method, the pump is connected in series with the outlet line regulating valve. The actual effect is like using a new pump system. The maximum output head of the pump is not changed, but the flow curve is attenuated.

Method 2: Bypass valve adjustment

In this method, the valve and the pump are connected in parallel. The actual effect is like the new pump system. The maximum output head of the pump changes a...

More

How to extend the service life of the centrifugal pump

How to extend the service life of the centrifugal pump

1. Selection and installation of centrifugal pumps

Centrifugal pumps should be selected according to the liquid being transported and checked for required performance, analytical suction, discharge conditions, intermittent or continuous operation, etc. Centrifugal pumps should normally be operated at or near the pressure and flow conditions specified by the manufacturer. The following review should be carried out when installing the pump:

1...

More

What are the role and advantages of the sewage pumping station?

What is the role of the sewage pumping station?

Our underground pipelines collect rainwater and sewage from the ground that relies on their own gravity to flow to the sewage treatment plant. However, since the sewage often carries impurities, it is easy to accumulate and block the pipelines, and the sewage pumping station is used to solve the problems of pipeline blockage and slow drainage.

1. Drainage for areas with low ground potential and easy to form waterlogging, reduce rainwater damage to...

More

How to solve the automatic start of fire pumps used for some years?

For the automatic start of fire pumps used for some years, the following measure should be done:

First, it is recommended to stop the operation of the fire pump, and then switch on the automatic switch of the electric control cabinet of the computer room to the local manual, then turn off the main circuit of the fire pump, carefully observe the situation, and make a record.

Secondly, check comprehensively inspection the fire pump itself to see if there is a fault. In particular, confirm w...

More

What factors determine the price of diesel engine fire pumps

What is the price of diesel engine fire pump? if the price of diesel engine fire pump is reasonable?

Looking at the market for diesel engine fire pumps, it is not difficult to find that price variance. When asked why they all have a set of rhetoric. As an experienced diesel engine fire pump manufacturer, Better Technology Co., Ltd. feels that there is a need to talk about the key factors that determine the diesel driven fire pump.

Factor 1: Material cost

Although nowadays, in order ...

More

15 common faults and elimination measures of the fire pumps

Usually, the fire pump is diagnosed during the maintenance process. The diagnosis of the fire pump failure is a key. Several common faults and elimination measures are given

below for the purpose of the fire pump fault diagnosis.

1) No liquid supply, insufficient liquid supply or insufficient pressure. The pump is not filled with water or is not properly vented

Measure: Check that the pump casing and inlet lines are all filled with liquid.

2) The speed is too low

Measure: Check if the m...

More

The Working Principle of The Diaphragm Pressure Tank

The working principle of the diaphragm pressure tank

The diaphragm type pressure tank is an energy storage device composed of a steel outer casing and a rubber diaphragm inner tank. The rubber diaphragm completely separates the water chamber and the air chamber, and when the external pressure water is filled into the inner tank of the diaphragm type pressure water tank. At the time, the air sealed in the tank is compressed. According to Boyle's law of gas, the volume of the gas is compressed and...

More

Do you know two types of pressure tanks – Better Technology CO., LTD.

Do you know two types of pressure tanks?

From the point of view of the water supply equipment, the pressure tank can be said to be necessary power for fire pumps. In general, pressure tanks are also classified, mainly in the following two types:

Air supply pressure tank

In the air supply pressure tank, the air is in direct contact with the water. After a period of time, the air reduces due to leakage and dissolution in the water, so that the amount of water gradually reduces. The start o...

More

How does pressure tank work? – Better Technology CO., LTD.

The Working Principle of the Pressure Tank

How does the fire pump work? How does pressure tank work? How does the fire pump deliver water? What is the driving force behind the operation of the fire pump? As we all know, the compositions of the fire pump include the impeller, the pump body, the pump shaft, the bearing, the seal ring, the motor, and other components. In addition, the working power is inseparable from the pressure tank.

The pressure tank is used in the closed water circulation sys...

More

How to ensure the ventilation of the diesel engine fire pump

How to ensure the ventilation of the diesel engine fire pump

Mechanical equipment generates heat after the long-term operation, and the heat becomes more pronounced over time. Long-term hot state, the life of the fire pump will be affected. The low cost is no problem, but what if you buy a diesel fire pump? In order to make the diesel engine fire pump quickly retreat the heat of the fuselage, it is obvious that the diesel engine fire pump should be ventilated. So, what can we do to make the die...

More

Working principle of the diesel engine fire pump

Working principle of the diesel engine fire pump

To better understand the diesel engine fire pump, we must first to know the working principle of the diesel fire pump.

During the working process of a diesel engine, there are many working cycles, and these cycles, through the four strokes of the air intake, compression, work, and exhaust. However, in general, the fuel used in diesel engine fire pumps is diesel. The characteristics of diesel oil are that the viscosity is larger than that of ga...

More

Why is the diesel engine fire pump engine difficult to start?

Why is the diesel engine fire pump engine difficult to start?

With regard to diesel engine fire pumps, the existence of the engine is the core, the power, and the premise of the work. Many times, because of the lack of understanding of diesel engine fire pumps, we are helpless in the face of failure. What is the difficulty in starting the diesel engine fire pump engine? What are the reasons for the difficulty in starting the diesel engine fire pump engine? What should I do if the diesel engine ...

More

The reasons why engine power of diesel engine fire pump is lower than normal

The reasons why the engine power of the diesel engine fire pump is lower than normal

Why is the engine power of the diesel engine fire pump low? In general, the engine power of a diesel fire pump is regulated, and it will not be low or high. In other words, the engine power of the diesel engine fire pump is lower than normal, which occurred a fault. Today, Better Technology CO., LTD. tell you about the reasons!

The engine power of the diesel fire pump is lower than normal, there are the reason...

More

The difference between fire pump and ordinary water pump

The difference between fire pump and ordinary water pump

Some customers said that when they first purchased the fire pump, they would always take detours. They felt that the fire pump and the ordinary water pump were the same, in order to control costs, use ordinary pumps as fire pumps. Well, today, Better Technology CO., LTD. will analyze the difference between the two.

The fire pump is an emergency pump, which is rarely used in normal times. For this reason, in order to ensure that the fire...

More

Fire pump rust removal methods – Better Technology CO., LTD.

Fire pump rust removal methods

First, manual rust removal.

Manual rust removal is the most common remedy for fire pump rusting. In the daily maintenance of fire pumps, when we find that the fire pump is rusting, we can directly use this method. So, how does Manual rust removal work? Quite simply, the rust is removed using a rust removal tool. For example, with a blade, gently scrape off only a little bit of rust on the fire pump, thus preventing the rusted surface from expanding. Manual rust r...

More

What are the key points of fire pump acceptance?

What are the key points of fire pump acceptance?

1. The main engine of the fire pump is divided into domestic and abroad. Many fire pumps claim to be from abroad, and the price is greatly improved. Actually, it is not. In addition, I want to tell that regardless of whether it is made in domestic or abroad, the total number of probes, buttons, and modules that cannot exceed 3,200 points. If this number is exceeded, the host should be added. Only such a fire pump can pass the acceptance.

2. The...

More

The Rust Spots on the Plating of the Fire Pump Actually Expose Problems

The Rust Spots on the Plating of the Fire Pump Actually Expose Problems

First, if the fire pump is not used for too long, the fire pump rust spots will prove that the electroplating time is not enough, which is a problem of the technological process;

Second, the rust spots on the plating of the fire pump are likely to be related to the environment. If the fire pump room is humid or the air is not circulating, the plating of the fire pump is prone to rust spots;

Third, it may be relate...

More

3 common problems in mechanical seal of the fire pump

3 common problems in the mechanical seal of the fire pump

Problem 1: The more the amount of spring compression, the sealing effect may be not better.

Why do I say that? During the use of the fire pump, you will find that the excessive compression of the spring will cause the friction pair to wear sharply and burn out instantly. Excessive compression will cause the spring to lose the ability to adjust the end face of the moving ring, resulting in seal failure.

Problem 2: The static rin...

More

4 Components of Fire Pump are Prone to Damage

4 Components of Fire Pump are Prone to Damage

First, Pump case for fire pump

In non-special cases, most of the fire pump cases are cast iron parts, unless a special corrosive medium, stainless steel structure. In the daily operation of the pump case of the fire pump, cracks may occur due to mechanical or thermal stress. When the pump is subjected to the impact of cavitation during work or is frozen when the water in the pump case is not drained in winter, it is also easy to be broken. If the d...

More

What is the principle that the fire pump water diversion is restricted?

What is the principle that the fire pump water suction is restricted?

After knowing a variety of fire pumps, you will find that the height of the fire pump water diversion is not as high as possible, and the time is not as long as possible. In fact, there are limits. Many people don't understand this. So, what is the principle of fire pump water suction restricted?

First, the fire pump water suction head

The principle of fire pump suction, I think many people know that after the vacuum is for...

More

Do You Know the Reasons and Measures of Fire Pump Cannot Suction?

The Reasons and Measures of Fire Pump Cannot Suction

Reasons for fire pump cannot suction:

Reason 1: The extrusion line is too thin and the pipeline loss is too large;

Reason 2: The use of the lift exceeds the design lift;

Reason 3: There is gas in the suction pipe or XBD fire pump;

Reason 4: The suction height exceeds the allowable range;

Reason 5: transporting hot, volatile media;

Reason 6: no perfusion liquid;

Cause 7: The flow path of the suction pipe, the outlet pipe or the fire pump...

More

Diesel Engine Fire Pump Features – Better Technology CO., LTD.

Diesel Engine Fire Pump Features - Better Technology CO., LTD.

Spectrum range: fire pump can use a single-stage end suction pump, a combination of multistage single-suction pumps, single-stage double-suction pumps and other kinds of pumps, pump or more kinds of parallel flow, wide pressure range.

Automatically: when the engine fire pump receives a valid signal fire, remote control start signal when the unit will start automatically; when the fire pump motor supply failure or lack of signal p...

More

The Installation of Fire Pumps – Better Technology CO., LTD.

The Installation of Fire Pumps - Better Technology CO., LTD.

The installation of fire pumps needs to pay more attention to many aspects. Different fire pumps have different types of installation requirements. What kind of installation is the most correct choice for fire pumps? What are the installation methods of the fire pump? For the fire pump installation problem, let us talk about it today.

First, Hard connection installation

Because the vibration of the fire pump is very small, the fire ...

More

Diesel engine fire pump inspection and daily management

Diesel engine fire pump inspection

In order to improve the diesel engine fire pump on the fire signal response capability, it is recommended to patrol once a week. Taking into account the water hammer effect and the

characteristics of the diesel engine itself, we should start the diesel engine at low speed, and then slowly accelerate to the fire required speed 1500r/min or (3000r/min).

When the water temperature, oil temperature can reach 60°C when the gradual deceleration, but still need to ...

More

The Root Cause of the Fire Pump cannot Suction

The Root Cause of the Fire Pump cannot Suction:

There is air in the pump body;

Accumulation of air in the Inlet pipe;

The bottom valve is not closed tightly;

The air extractor packing leaks;

The valve or the door is not closed tightly.

The fire pump can't suck the water, the following ways can help you:

Press the water up first, then fill the pump body with water, then turn it on;

Check whether the check valve is closed tightly and whether the pipeline and the joi...

More

How to reduce diesel fire pump fuel consumption effectively?

5 Fuel-efficient Tips for Diesel Fire Pump

Many people say that the diesel fire pump is expensive, and also consume diesel. Today, I will tell you five fuel-efficient tips for diesel fire pump.

Tip 1: Increase the temperature of the diesel engine cooling water. The increase of water temperature can make the diesel burn more completely, the viscosity of the oil will be smaller, the movement resistance can be reduced, and the fuel saving effect can be achieved.

Tip 2: Adjust the fuel injection...

More

The armature of the fire pump – Better Technology CO., LTD.

The armature of the fire pump

The so-called armature is the part of the motor that is equipped with a wire. The relative movement of the wire to the magnetic field generates an induced electromotive force in the wire, or the energized wire is subjected to an ampere force in the magnetic field to cause it to rotate in the magnetic field. A key and pivotal component in the process of converting mechanical energy from electrical energy. For a generator, it is a component that produces an electromo...

More

Precautions for excessive fire pump temperature

Precautions for excessive fire pump temperature

First of all, in order to avoid the fire pump get excessive heat for long-time operation, the pump has to release heat, so how to deal with? naturally, the pump needs to be installed in a well-ventilated place. This is why fire pump placement rooms will be set up in some places. The fire pump needs a certain area for the room to be placed, and the air circulation in the pump room must be good. If the conditions are poor, at least ensure a certain s...

More

What is the fire pump?

What is the fire pump?

What is the fire pump? A pump is a machine used to increase the pressure of a liquid or gas to transport them. It is also a device used to move liquids, gases, or special fluid media. That is a machine that works on fluids. It transfers the mechanical energy of the prime mover or other external energy to the liquid, increases the energy of the liquid. Pumps are mainly used to transport liquids including water, oil, acid and alkali, emulsions, suspension emulsions, and liqu...

More

The root cause of insufficient pressure of the submersible fire pump

As we all know, the submersible fire pump is used underwater. Relative to the ordinary fire pump, there will naturally be more problems. So, what are the common problems with submersible fire pump?

1, Rust, such as the impeller corrosion;

2, Short life;

3, Easy to block;

4. Disadvantageous for maintenance;

5, The fixing screw is loose, so that the spring loses its effect;

6. The shaft sleeve wear too much;

7, The pressure is insufficient, the pump can not be used normally.

The submersibl...

More

3 main causes of pump vibration problems

3 main causes of pump vibration problems

After using the fire pump for a period of time, you will find that the fire pump becomes more and more clumsy during the operation. The most obvious phenomenon is that the vibration becomes frequent and more serious. So, what causes vibration of the fire pump? There are three main causes of pump vibration.

Causes 1: Pump Impeller Imbalance

Pump Impeller Imbalance is one of the key factors. When the impeller is unbalanced, One reason is impeller worn ou...

More

The Right Way to Clean Fire Pumps

The Right Way to Clean Fire Pumps

Fire pump, as the important equipment in the fire pump field, its quality was the key to decide the fire safety. When the fire pump was placed for a long time, there will be some problems, for example, sanitation, clogging, and corrosion. So fire pump, in fact, needs to be cleaned. Grasping the right way to clean fire pumps is necessary.

In order to remove surface stains more quickly, some cleaning products such as detergents are used to clean the fire p...

More

5 reasons of the high temperature of the fire pump bearings

5 reasons for the high temperature of the fire pump bearings

Reason 1: Because the axial thrust suddenly increases during the operation of the fire pump, for example, when the balance plate and the balance ring of the fire pump are seriously damaged, the thrust will not be increased, and the axial load of the bearing will be increased, thereby causing the fire pump. The bearing temperature is too high.

Reason 2: The fire pump shaft is bent or distracted, which will cause the fire pump to...

More

5 Direct Reasons for Fire Pump Shaft Break

5 Direct Reasons for Fire Pump Shaft Break

Can pump shaft break? Many people are confused about these, So if the reason is its quality, or something else. Actually, more problems are made because of its incorrect operation. The followings are direct reasons for fire pump shaft break.

The precision of the pump shaft casting is not enough, resulting in the fracture of the pump shaft of the fire pump;

Because the fire pump is placed in the environment for a long time, there will be some corr...

More

Some Precautions Before starting fire pump

Some Precautions Before Starting Fire Pump

What are the precautions before the fire pump start? Generally, before using, it is necessary to check the status of the fire pump first, including the following aspects:

Check if the fire pump can work properly

When testing the fire pump, the return valve should be fully open, and the valve should be closed, and then restored to the normal position after the trial. In addition, when you need water or when it is an emergency, open the valve at ...

More

Correct maintenance of fire pumps